Light insulation fire brick

Light insulation fire brick

Lightweight insulating bricks complying with JM/ASTM standards

are made from high purity refractory clay and, in higher temperature applications, with alumina.

Lightweight insulating bricks are produced in high purity and at high temperatures using alumina.

Thermal insulation layers are used as supporting and main layers in high-temperature industrial furnaces and provide good physical, mechanical and thermal performance.

Insulating bricks consist of carefully graded organic materials that are burned and removed during the manufacturing process, creating a uniform and controlled porosity within the insulating bricks. Each grade of lightweight insulating brick is formulated to withstand the temperature conditions defined for it, including the temperature grades of insulating bricks.

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920

What is Mullite Insulating Firebrick

Mullite Insulating fire bricks are usually divided into two main types, general ones with a character of light weight and soft which have better advantages of insulation, while another type is with better cold crushing strength for better constructions. The insulating firebricks color vary to be different , but most often they are white and light brown. As the insulating firebricks body are made of tiny air space similar to honeycomb that the bricks have a excellent insulating properties.

Where Insulating Firebricks are used.

light weight firebricks are used in a wide ranges industrial furnace and kilns , and also used on the hobby kilns heated up with either electric spiral elements or gas burners, they can be used for hot face furnace lining or outer back-up heat lining insulation, mullite Insulating bricks are also refractory materials as they can resist a very high temperature, but the difference between IFB and dense refractory firebricks is that they have a very low thermal conductivity and don’t absorb the heat well at all, it is why they are ideal materials for heat insulation application, so if you use the insulating bricks rightly at the outer side of the heavy firebricks walls, vault or under the floor bricks and slab , it will keep the heat in its chamber body mass from escaping, in this way it can save energy efficiently.

Lightweight thermal insulation refractory brick refers to refractory products with high porosity, small body density and low thermal conductivity, and is a kind of refractory materials. Its main characteristics are its porous structure (porosity is generally 40% ~ 85%) and high heat insulation. In terms of construction, lightweight insulation bricks are light in weight, which greatly reduces the masonry weight of the kiln. Simple and convenient construction, reducing labor intensity, improve work efficiency.

The operating temperature range of Insulation Fire Brick is 900℃ to 1600℃. The product is made of high-quality and ultra-pure raw materials and is strictly filled according to grade. It is mainly used for thermal insulation of thermal equipment and industrial kilns. It can be used in areas where there is no strong high-temperature molten material erosion and erosion. The product can reduce the basic cost, and has good machinability and easy construction. Using this product in construction can reduce the weight of the building and greatly reduce the overall cost of the building.

Advantages

1. Economic: Insulation Fire Brick can reduce the foundation cost, reduce the cross-section of the frame, save reinforced concrete, and can greatly save the overall cost of the building. Compared with solid clay bricks, the design and use of light bricks can reduce the total cost by more than 5%.

2. Practicability: The use of lightweight bricks can increase the area of use. At the same time, due to the thermal insulation of the aerated concrete, the thermal insulation effect is good. In hot summer days, the indoor temperature is 2-3°C lower than solid clay bricks. energy consumption.

3. Constructability: Lightweight bricks have good machinability, and construction is convenient and simple. Due to its large size and light weight, it can reduce labor intensity, improve construction efficiency, and shorten the construction period.

Features

Lower thermal conductivity

Lower bulk density

Light weight character

Lower creep rate in high temp

Good thermal shock resistance performance

Higher temperate resistant with good refractoriness

Applications

Insulation Fire Brick can be applied to the refractory lining of hot surfaces or the back insulation of other refractory materials; it can also be used as the refractory lining or insulation materials of petroleum or chemical industry furnaces, such as ethylene pyrolysis furnaces, tube furnaces, and synthetic ammonia Furnace, gas generator and high temperature shuttle kiln etc.

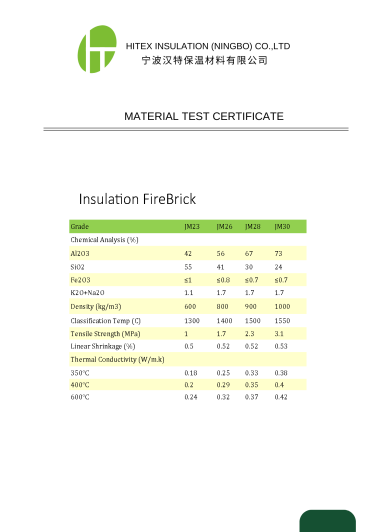

Specifications

Alumina contents range from 40% to 80%

Widely used throughout metallurgical industry

Features of lightweight insulating bricks

Low impurity

Low thermal conductivity and heat storage

High strength and resistance

Good shock resistance

Exact dimensions

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920