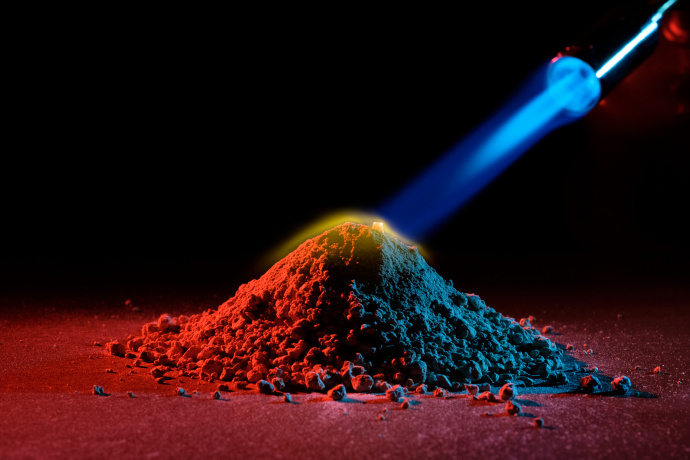

inflammable mass

Non-combustible, refractory mass

Refractory materials refer to all materials whose physical, chemical, mechanical, and thermomechanical properties do not change at high temperatures and, in particular, exhibit the necessary resistance to pressure, abrasion, thermal shock, and chemical corrosion.

Types of refractory masses according to the type of raw materials:

Refractories are sold in a wide variety on the market. Refractories are usually classified based on their chemical properties, method of use, and composition. Depending on the type of material used in the refractory, they can be divided into different types.

Narun Kala Tadbir's expert consultants will help you select and purchase the product you want at the best price.

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920

Refractories are divided into different types based on their constituent compounds, one of the best-selling of which is alumina refractory. This refractory is composed of two important compounds: alumina (Al2O3) and silicon carbide (SiC), each of which can have high resistance to heat.

This refractory mass has refractory properties and is very resistant to heat. Alumina refractory mass can be used to build induction furnaces.

1. Magnesite masses

2. Aluminous and aluminosilicate masses

It is a type of refractory material whose main component is magnesium carbonate and has many applications in industries due to its chemical stability and high heat resistance.

The most common types of refractory masses based on their constituent components are:

Narun Kala Tadbir's expert consultants will help you select and purchase the product you want at the best price.

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920

• Sprinkler loads

Sprayable refractory mass consists of finely divided, powdered refractory materials that are sprayed onto the walls of furnaces using a gun or gunning method. Sprayable refractory mass is often used for furnace repair and maintenance to extend the life of the furnace. This type of mass provides maximum adhesion to the surface.

These materials are called castable because they must be poured into a mold to take their specific shape. The amount of water in the structure of these materials must be sufficient to allow them to be easily poured and filled into the mold. Therefore, it is expected that a relatively high percentage of water will be used for their initial shaping.

The higher the alumina percentage, the higher the refractory and mechanical strength of the mass.

• Violable crimes

Knockable refractory masses are amorphous or powdered alumina, magnesia or silica refractory mixtures that are adjusted by knocking and granulating according to the installation requirements. Knockable refractory matrices ultimately result in a dense and uniform refractory coating with high density and minimal porosity. Knockable refractory masses also offer good resistance to stress and thermal shock.

Impact refractory masses are mainly used in the bottom of equipment exposed to heat or in the gaps between its components. In addition, it can be a good option for use in the safety layer of this category of industrial equipment. Impact refractory masses, depending on the ingredients, use two types of bonding systems: air-setting (air-hardening) and heat-setting (thermo-hardening).

• Pourable mass

Castable refractory is a type of amorphous refractory material that can withstand and be used in very high temperature conditions, such as high temperature industrial furnaces. The ingredients of castable refractory are mainly silicates and aluminates. These refractories are classified into two categories: light insulating masses and heavy refractory masses.

Alumina refractory masses are divided into 4different categories depending on particle size and use:

• Plastic particles

Plastic refractory masses are a special type of monolithic refractories that are known for their ductility and moldability. These masses are prefabricated materials that do not require prior preparation.

3.Silica masses

Silica refractory clay is the best refractory for melting cast iron, plain carbon and low alloy steels. The grain size of silica refractory clay is such that it creates maximum compressibility. Other characteristics of these clays include their low thermal conductivity.

Narun Kala Tadbir's expert consultants will help you select and purchase the product you want at the best price.

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920

سبد خرید