Oven furniture

Kiln furniture refers to refractory (refractory) and engineering ceramic components that are used as kiln equipment and generally to hold ceramic and refractory products during firing in the kiln.

The conditions governing the kiln furniture components are such that these components must have the necessary refractory properties depending on the application temperature and be resistant to deformation and thermal shock due to repeated heating and cooling cycles.

These parts have a wide variety of shapes and include simple to complex shapes such as refractory base, refractory ingot, refractory profile, refractory shoe and various types of refractory plates. Various compositions based on Cordierite Mullite and Silicon Carbide or SiC and Alumina plates are used to manufacture these products.

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920

Available parts for furnace furniture

Types of refractory base

Refractory ingots or refractory profiles made of sic plate

Refractory shoes and fittings

Sheets produced by extruder method

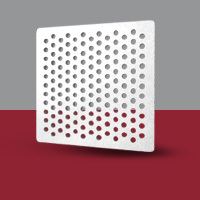

Cordierite mullite refractory plate, mesh and plain

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920

Furnishing furniture applications

Industrial ceramics

brick making

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920

Silicon carbide body refractory plates

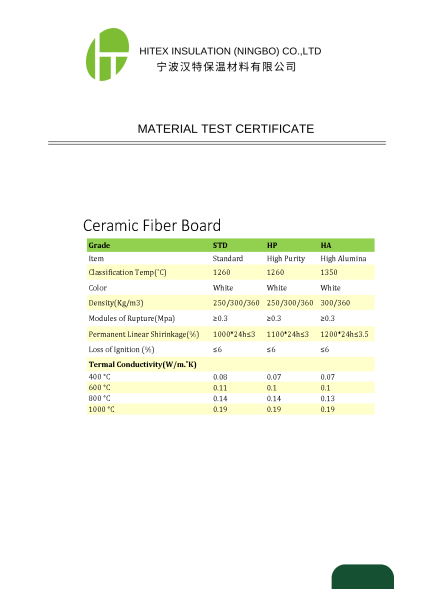

If high thermal transfer and optimum strength at high temperatures are required, as well as prevention of peeling.(Spalling Resistance)

And most importantly, resistance to thermal shock, refractory furnace plates are used in the arrangement of furnace carriages.

Porcelain and sanitary ware industries

Insulation industries

Defense industries

High strength

Low thermal conductivity

Silicon carbide furnace furniture specifications

کارکرد مناسب در دمای بالا 1600 درجه