Ceramic paper

Ceramic paper

Ceramic paper and ceramic mat are produced in a wet process from a mixture of ceramic fibers along with organic additives and chemical adhesives. The wet process allows for the separation of non-fibrous grains from the fibers, providing better thermal insulation and easier transportation.

Due to its flexibility and high resistance to thermal shock, resistance to tearing, easy cutting, easy and suitable shaping, and light weight, refractory ceramic paper is a very suitable insulator for use in various industries and is also a very good alternative to obsolete materials such as asbestos.

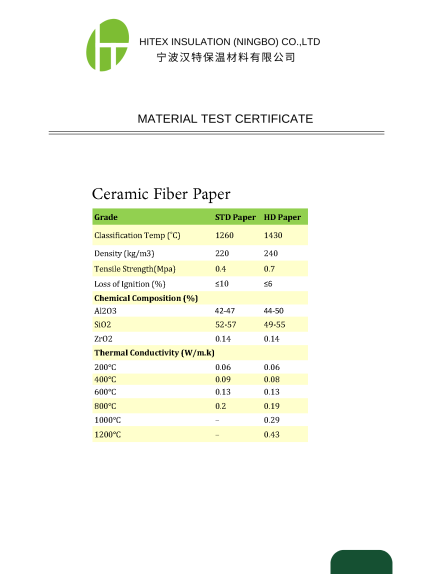

Ceramic papers are produced in two temperature grades of 1260 and 1430 degrees. Fireproof paper is available in rolls in different thicknesses from 1 mil to 5 mil. For information on prices and brands of ceramic paper, contact Naroon Kala Tadbir Company.

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920

What Is Ceramic Fiber Paper? Applications, Benefits, and Manufacturing Process

:Introduction

Ceramic fiber paper is a specialized refractory material made from high-purity alumina-silica fibers. Lightweight, flexible, and heat-resistant, it is widely used in industrial applications that require insulation and thermal protection. In this article, we’ll explore the main applications, benefits, and manufacturing process of ceramic fiber paper.

Applications of Ceramic Fiber Paper

1. Thermal Insulation in Furnaces and Kilns

Ceramic fiber paper is commonly used as a lining material in high-temperature environments such as industrial furnaces, kilns, and boilers. It helps prevent heat loss and improves energy efficiency.

2. Gasket and Sealing Material

Due to its excellent flexibility and heat resistance, ceramic fiber paper is ideal for high-temperature gaskets and seals, especially in metal and glass manufacturing industries.

3. Heat Shields in Automotive and Aerospace Industries

It is also used in automotive heat shields and aerospace components, where it acts as a thermal barrier to protect equipment from extreme temperatures.

4. Fire Protection Systems

Ceramic fiber paper is a key component in fireproof panels and doors. Its non-combustible nature makes it suitable for passive fire protection.

5. Electrical Insulation

Because of its dielectric properties, ceramic fiber paper is also used for insulating high-voltage electrical components.

Benefits of Ceramic Fiber Paper

• High Heat Resistance: Can withstand temperatures up to 1260°C (2300°F) or higher, depending on the grade.

• Lightweight and Flexible: Easy to cut, shape, and install without special tools.

• Low Thermal Conductivity: Offers excellent thermal insulation.

• Chemical Stability: Resistant to most corrosive chemicals and thermal shock.

• Environmentally Safe: Asbestos-free and safe to handle with basic protection.

How Is Ceramic Fiber Paper Made?

The manufacturing process of ceramic fiber paper involves the following key steps:

1. Fiber Production

High-purity raw materials such as alumina and silica are melted and spun into fibers using a centrifuge or blowing process.

2. Pulping and Slurrying

The ceramic fibers are mixed with organic binders and water to form a pulp slurry.

3. Sheet Formation

The slurry is poured onto a moving screen or felt belt to form a thin, uniform sheet. The thickness can be adjusted depending on the required application.

4. Drying and Cutting

The formed sheet is dried in ovens, removing moisture and partially burning out organic content. It is then cut into rolls or sheets of desired size.

5. Optional Heat Treatment

In some cases, the paper is heat-treated to remove binders completely for ultra-pure applications.

Conclusion

Ceramic fiber paper is a vital material in industries requiring high-temperature insulation, sealing, and fire protection. Its outstanding thermal and physical properties make it a reliable choice for modern engineering applications. As industries continue to demand better performance under extreme conditions, ceramic fiber paper remains a cost-effective and efficient solution.

High tensile strength

The ability to absorb sound

High thermal resistance

Resistance to chemical corrosion

Features of ceramic paper

Ease of production

High thermal reflectivity

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920

As gaskets and packing

Alternative to asbestos

Refractory brick expansion joint filler