Fiberglass fabric

Fiberglass fabric

Fiberglass fabrics are made from glass fibers with a temperature tolerance of 550 degrees Celsius and are divided into two groups: plain and coated fabrics. Coating with various polymers such as Teflon or silicone is done to prevent air or moisture from passing through the fabric pores.

Uncoated fiberglass fabric

Foiled fiberglass fabric

PTFE Fiberglass Fabric

Silicone Fiberglass Fabric

Types of uncoated fiberglass fabrics

100g fiberglass fabric - with E-glass grade:

Because of its white appearance and thinness, this product is also called silk fabric. The weight of the rolls of this fabric is 20 kilos and the length of each roll is 200 meters.

200g fiberglass fabric - with C-glass grade:

Because of its white appearance and thinness, this product is also called silk fabric. The weight of the rolls of this fabric is 20 kilos and the length of each roll is 100 meters.

430g fiberglass fabric – C-glass grade:

Each roll of this fabric weighs 20 kilograms and is 100 meters long.

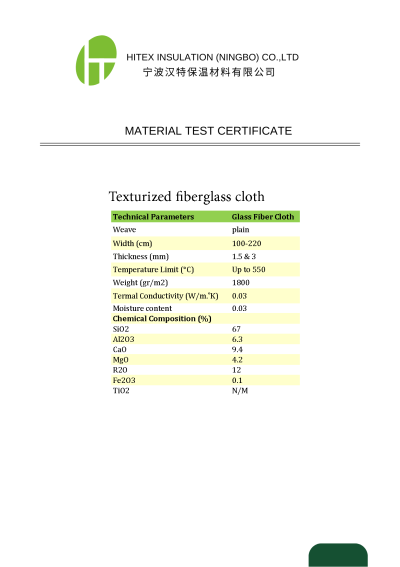

Fiberglass fabric thickness 1.5 and 3:

These fabrics are the most widely used among other fiberglass fabrics. Usually, the weight of these fabrics is 50 kilograms and their length is 100 meters.

Mechanical strength: The strength of various types of fiberglass fabrics is even greater than that of steel, so it is highly effective.

Can be combined with many synthetic resins and can have different sizes.

Electrical insulation: These fabrics are good insulators against electricity, even at low thickness.

No rot: Fiberglass does not rot and is immune to insect chewing.

Stability: These fabrics are not sensitive to temperature changes and have a low coefficient of linear expansion.

Features of fiberglass fabric

Dielectric permeability: This property makes it widely used in electromagnetic applications.

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920

Using fiberglass mesh to resist rust and create a contrasting color that helps in washing cars in car washes.

Use of fiberglass in aquariums and mesh in large fountains to protect lamps and headers

Cooling towers are always wet, so they must be resistant to rust and corrosion. The use of fiberglass makes these towers safe.

Use of fiberglass railings in areas of the electrical refinery that are susceptible to chemical corrosion

On dock s to protect against corrosion and rust by sea water

Application of fiberglass fabric

In industrial areas, electricity generation is possible due to the non-conductivity of these materials.

In paper and bleach factories due to resistance to chemical corrosion

Manufacturing parts in the aerospace, military, and military armor industries

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920

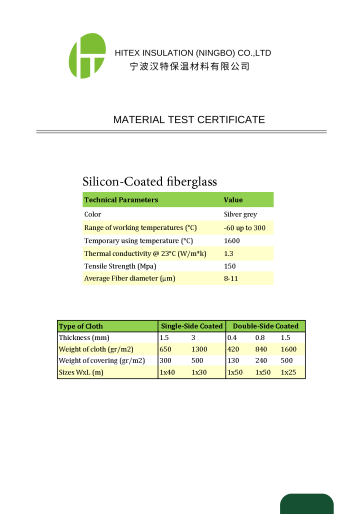

Silicone coated fiberglass fabric

Silicone fiberglass fabric is produced in two forms: single-sided silicone and double-sided silicone. 430-gram fabric is used to produce this product. In single-sided silicone fiberglass fabric, approximately 80 grams of gray silicone is used per square meter, and in double-sided silicone fiberglass fabric, the amount of silicone used per square meter is 130 grams. The rolls of this product are 50 meters long.

Resistance to cold and heat, it can work continuously at temperatures from -70 ºC to 280 ℃ and intermittently up to temperatures of 550 ℃.

High strength, soft and flexible.

Resistance to ozone, oxygen, sunlight and wear, long life of up to 10 years.

Resistance to abrasion, bending, tearing and punctures

Good electrical insulation, dielectric constant 3~3.2, withstand voltage between 20~50KV/mm.

Features of silicone fiberglass fabric

Resistant to diluted acids and alkalis

Flame and smoke retardant

Contact us:

021-88811733

021-88811734

021-88811735

0910 7100915 - 0910 7100920

Use as conveyor belts or refractory conveyor belts

Use of fiberglass in aquariums and mesh in large fountains to protect lamps and headers

For the construction of manholes in petrochemical plants, power plants, platforms and oil tanks.

Use in air ducts or channels in air conditioning

Widely used in aerospace, chemical, petroleum, power generation equipment, machinery and metallurgy industries.

Application of silicone fiberglass fabric

As a welding blanket

As a thermal cover

As fireproof curtains

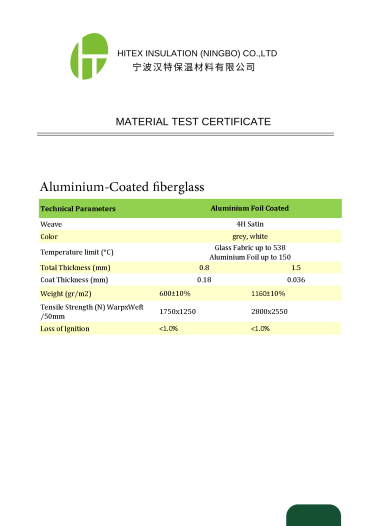

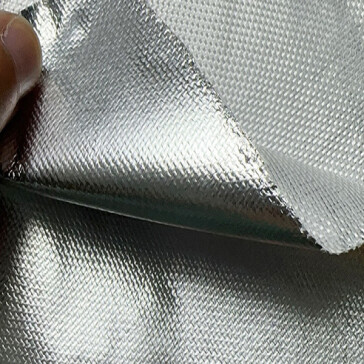

In these fabrics, aluminum foil is attached to one side of the fabric, which causes heat to radiate outward and prevents heat from passing through the fabric. In fact, it reduces heat transfer and, due to conductivity, causes heat to spread across the surface of the fabric. These fabrics are mostly available in thicknesses of 0.5, 0.8, 1.5, and 3 mils.

Foiled fiberglass fabric

Excellent performance against constant and standard heat up to 550 degrees Celsius

High flexibility, very high shaping ability

Waterproof – anti-scratch and anti-corrosion

Sound resistant

Features of foiled fiberglass fabric

To protect oil pipelines and…

In the chemical industry

To protect the car engine

In the shipping industry

Applications of silicone fiberglass fabric

For fire isolation in firefighting clothing and…

Thermal insulation of steam pipeline

Motor output manifold

Making fire-resistant clothing

Protecting wires, cables, hoses, hydraulics

Sealing furnace ducts

Teflon coated fiberglass fabric ptf

Teflon polymer is used to coat this type of fabric and is produced in two forms: plain and adhesive backed. The most commonly used thicknesses of this fabric are 0.13 and 0.25. They are packaged in 50 meter rolls.

Heat resistant from -40°C to 280°C

Excellent chemical resistance

Very high flexibility

Against wear and corrosion

Features of Teflon coated fiberglass fabric

For fire isolation in firefighting clothing and…

Thermal insulation of steam pipeline